Compressor

| Compressor | : | Construction – Open / Hermetically |

| Sealed / Semisealed | ||

| Compressor Type | : | Reciprocating / Scroll / Screw |

| Refrigerant Gas | : | R-22 / R-134a / R-404a / R-407c / R-410a / |

| R-507 / and R-717 Ammonia | ||

| Application / Use | : | Air Conditioning, Refrigeration – |

| for Comfort or Industrial Cooling |

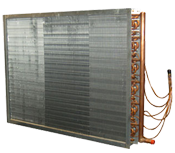

Condensor

Air Cooled

| Type | : | Forced Draft Heat Exchanger |

| Coil – DX or Chilled water | ||

| Capacity | : | 1 to 200 TR (Any tailor made design, |

| size, pattern or sample) | ||

| Construction | : | Tube – Copper Plain and IG / SS-304 / MS |

| Fins – Aluminium / SS-304 / Copper / GI Body – GI / Al / SS-304 | ||

| Refrigerant Gas | : | R-22 / R-134a / R-404a / R-407c / R-410a / |

| R-507 / & R-717 Ammonia | ||

| Features | : | Heavy duty designed with suitable material |

| to deliver best efficiency | ||

| Application / Use | : | Air Conditioning / Refrigeration / |

| Industrial Heat rejection-absorbtion |

Water Cooled

| Type | : | Shell and Tube type design / Tube in Tube |

| Capacity | : | 1 to 200 TR |

| Construction | : | Tube MOC – Copper / CUNI |

| (90/10% – 70/30%) / SS-304 / MS Tube Type – Integrally finned and IG / Intigrally finned and inside plain | ||

| Refrigerant Gas | : | R-22 / R-134a / R-404a / R-407c / R-410a / |

| R-507 / and R-717 Ammonia | ||

| Features | : | Heavy duty designed with suitable material |

| to deliver best efficiency | ||

| Application / Use | : | Air Conditioning / Refrigeration / Industrial |

| Heat rejection-absorbtion |

Evaporator

Air Based

| Type | : | Forced Draft Heat Exchanger Coil – |

| DX or Chilled water | ||

| Capacity | : | 1 to 200 TR (Any tailor made design, |

| size, pattern or sample) | ||

| Construction | : | Tube – Copper Plain and IG / SS-304 / MS |

| Fins – Aluminium / SS-304 / Copper / GI Body – GI / Al / SS-304 | ||

| Refrigerant Gas | : | R-22 / R-134a / R-404a / R-407c / R-410a / |

| R-507 / and R-717 Ammonia | ||

| Features | : | Heavy duty designed with suitable |

| material to deliver best efficiency | ||

| Application / Use | : | Air Conditioning / Refrigeration / Industrial |

| Heat rejection-absorbtion |

Water Based

| Type | : | Shell and Tube type design – Straight and |

| U-Bundle Design / Tube in Tube / Shell in Shell | ||

| Capacity | 1 to 200 TR | |

| Construction | : | Tube MOC – Copper / CUNI (90/10% – |

| 70/30%) / SS-304 / MS Tube Type – Plain / Inner Grooved | ||

| Baffles | : | Non Corrosive material / MS |

| Refrigerant Gas | : | R-22 / R-134a / R-404a / R-407c / R-410a / |

| R-507 / and R-717 Ammonia | ||

| Features | : | Heavy duty designed with suitable material |

| to deliver best efficiency | ||

| Application / Use | : | Air Conditioning / Refrigeration / |

| Industrial Heat rejection-absorbtion |

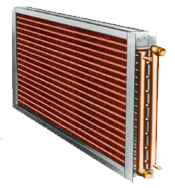

Heat Exchanger Coil

| Type | : | Forced Draft Heat Exchanger Coil – |

| DX or Chilled water | ||

| Capacity | : | 1 to 100 TR (Any tailor made design, |

| size, pattern or sample) | ||

| Construction | : | Seam jointing / Welded Tube – Copper |

| Plain and IG / SS-304 / MS Fins – Aluminium / SS-304 / Copper / GI Body – GI / Al / SS-304 | ||

| Features | : | Heavy duty designed with suitable |

| material to deliver best efficiency | ||

| Application | : | Air Conditioning / Refrigeration / |

| Industrial Heat rejection-absorbtion |

Plate Type Heat Exchanger (PHE / BPHE / GPHE)

| Type | : | BPHE – Brazed Plate Heat Exchanger |

| GPHE – Gasketed Plate Heat Exchanger Semi Welded Gasketed Plate Heat Exchanger | ||

| Capacity | : | 1 to 200 TR |

| Construction | : | Plates – SS-304 / 316 |

| Jointing Method | : | Copper Brazing / Complete SS welding |

| Option | : | Single or multi circuit |

| Features | : | Heavy duty designed with suitable material |

| to deliver best efficiency | ||

| Application | : | Air Conditioning / Refrigeration / |

| Industrial Heat rejection-absorbtion |

Eco System Controller

| Contact | : | Technical Team directly for further details |